Guide to Hydraulic Hose Fittings

Hydraulic fittings may be observed in nearly each industry, but no longer all hydraulic hose fittings can do the same process. Given the quantity of their usage, it’s crucial to pick the proper sort of hydraulic fitting to suit your application , hose length and assembly.

Whether you're a expert inside the industry or simply getting to know the ropes, you need so one can discover the proper hydraulic fitting for the activity. We’re right here to make it clean for our readers with a whole manual to varieties of hydraulic hose fittings, their packages and the way to use them. Maintain studying to study everything you want to realize.

Table of Contents

1.What Are Hydraulic Fittings?

Hydraulic fittings are parts used to attach hydraulic hoses to other additives. Hydraulic couplings are used in a spread of machines and system across all main industries. They're used in manufacturing hydraulics and meeting lines , water and sewage structures, oil refineries, and creation site hydraulics , to call a few.

There are distinctive styles of hydraulic fittings; every one serves a distinctive purpose. In addition they are available extraordinary sizes, substances, varieties of seals, and temperature and pressure tolerances. For instance, a hydraulic fitting can either allow or save you the waft of fluid. In some instances, the fittings are dual-use and can do both. However the maximum vital first-class of a hydraulic fitting is how effective it is in growing a tight seal.

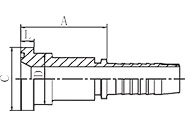

The two principal styles of hydraulic fittings are crimped fittings and area attachable fittings. Because the call implies, field attachable fittings or reusable fittings encompass a socket and a nipple and may be installed everywhere with out using a crimper.

A crimped fitting is a permanent fitting that is sealed with acrimping machine . Crimped fittings are plenty more at ease than a field attachable fitting however do want the equipment to make the seal. At the same time as many crimping machines are large gadgets that stay inside the workshop, there are also many portable and hand-held hydraulic crimpers to bridge the gap between crimp couplings and area attachable fittings.

2.What Are Hydraulic Hose Fittings Made Of?

Hydraulic fittings can be made from many materials, the most common ones being plastic, stainless steel, or brass. The type of assembly or industry application usually determines what material is suitable.

Let’s take a closer look at the most common materials used in hydraulic fittings:

Plastic Hydraulic Fittings – these types are much more resistant to corrosion compared to their metal counterparts. However, they are physically weaker and less durable. This is why they are not preferred for hydraulic applications despite the low cost. Metal fittings are better suited for high-pressure ratings found in industrial applications .

Steel Hydraulic Fittings – these types of fittings are made of steel alloys which means they are far more durable than their plastic counterparts. For instance, carbon steel fittings can withstand temperatures from -53°C up to 260°C.

Stainless Steel Fittings – as the name suggests, these are the stainless steel variant of steel hydraulic fittings. Stainless steel fittings are utilised in situations where they would need to withstand temperatures ranging from -253°C up to 648°C. Their tough nature makes them the choice of fitting for highly corrosive environments. Fittings made from this material are generally rated up to 10,000 psi, with some special designs capable of withstanding up to 20,000 psi. The primary drawback for these is their high price, which usually prompts industries to consider alternatives for less hard-wearing applications.

Brass Fittings – these are not as strong or durable as their stainless steel counterparts. However, they can provide a tight seal that prevents leaks and meet SAE (Society of Automotive Engineers), ISO (International Organization for Standardization), DIN (Deutsches Institute für Normung), and JIS (Japanese Industrial Standards) standards, among others. Brass fittings are rated for temperatures from -53°C up to 204°C, and pressures up to 3,000 psi.

Aluminium Fittings – hydraulic fittings made from aluminium are less common, but do exist and are used in certain applications. They are lighter than steel but are resistant to corrosion. These qualities make them preferable in transportation hydraulics such as the automotive industry.

3.Types Of Hydraulic Fittings

Factors to don't forget while selecting a hydraulic fitting include deciding whether or not to apply one that is permanent or reusable, in addition to the sort of port connections, becoming ends, and the sealing technique.

Don't forget to seek advice from an professional or expert when figuring out which sort of hydraulic fitting to apply. Every kind has its own use case state of affairs that would not be appropriate for others. The use of the wrong fitting ought to lead to malfunctions, damages, or maybe endanger lives.

4.How To Identify Hydraulic Hose Fittings

To properly identify the hydraulic hose fitting for the application, determine the type of fitting, match the port connection with that of the hose, and determine the type of seal and fitting design and size of the thread.

1. Determine the type of fitting – check to see if the fitting is crimped or reusable. Newer equipment and connections are usually crimped.

2. Match the port connection with that of the hose – another important part is to make sure that the port connection matches the one on the hydraulic hose. Refer to the table below.

3. Determine the type of seal – referring to the physical dimensions and technical characteristics, identify whether it is using an O-Ring, a Mated Angle, or a Tapered Thread. Mated Angles are based on straight and parallel thread types, in which the male and female units will form the seal. Tapered Threads will have the threads on the outside if it is a male unit and on the inside if it is female. Lastly, O-Rings (ORFS) will already include the seal.

4. Determine the fitting design and size of the thread – refer to the list below for the most common and widely used hydraulic fittings.

5. NPT /NPTF – this is the most commonly used type of thread in North America and is recognisable by its tapered inner diameter and outer diameter. This creates a self-sealing fitting.

6. BSPT – also known as the British Thread Type, is standard fittings adopted internationally for making connections and sealing pipe ends.

7. Metric Taper – most common in Europe. The male has a 24° sealing angle cone seat with straight metric threads.The female has a 24° convex cone with O-ring and a swivel straight metric threaded nut.It has a cylindrical inner and outer diameter precise in millimeters.

8. SAE Straight Thread – a thread type known for its reliability and reusability-has excellent sealing due to its 90-durometer O-rings.SAE thread port and mating stud end.

9. ISO 6162 – this is equipped with a straight thread O-ring port, useful for diagnostic port applications.

10. JIS -B2351 – JIS is equivalent to BSP thread (both tapered and parallel). But JIS has a 30° flared seat in the female variant and cone in the male variant (similar to the seat/cone system in JIC fittings)

11. DIN Metric – Since this thread type uses the German Industrial Standard, they are popular throughout Germany and the majority of Europe.

12. BSPP – These are BSPP connectors that follow the standard British thread dimensions.

13. Flange – The 4-bolt split flange (or full flange) fitting is used worldwide for connecting high pressure hoses typically to pumps, motors and cylinders, where the hose assemblies are subjected to large pressure loadings.

5.How Do You Choose the End Fittings For a Hydraulic Hose?

The criteria for choosing the right end fittings for hydraulic hoses are size, material, temperature, pressure, application, and assembly. The proper assessment of these criteria is critical to ensure the safety and reliability of the connections. Each of the factors mentioned above are detailed below:

Size – when it comes to the size, the important measurements to consider are the internal and external diameters of the hydraulic fittings. The diameters have to be compatible with that of the hydraulic hose. Fittings over or under-sized won’t be sealed properly and cause the connection to fail or leak.

Material – different materials have different properties, which affect and determine the compatibility with the fluid. As such, making sure that the fitting is compatible with both the hydraulic fluid and the working environment is critical. Determine both and choose between brass, aluminium, steel, or stainless steel. The most widely-used sealing materials are O-rings made from NBR (Nitrile).

Temperature – aside from ensuring that the different materials that make up hydraulic fittings are resistant to the operating temperatures, the type of fittings should also be considered.

Pressure – the amount of pressure the hydraulic fitting is subjected to differ across varying industries and applications. Make sure that the fittings are rated for the pressure range required. Operating beyond the rated pressure may cause leaks and even danger to people in the working environment.

Application – depending on the industry or application, the fittings could be used for either mixing or distributing. As such, hydraulic fittings such as the T-shape and the cross-shape come into consideration.

Assembly – hydraulic systems that require frequent connections and disconnections of the hose or tube should consider quick-connect fittings. For instance, hydraulic compression fittings can also remove the need to weld or solder the fitting. It uses a compression nut that tightens against the ferrule, creating a tight seal.

Permanence – Needing a permanent fitting or one that can be removed and changed frequently will affect the fitting style you choose. If this fitting is going to be changed often, a field attachable fitting will work just fine, but if you need something permanent and strong, using a crimping machine to crimp your fitting permanently is the perfect option.

Aside from this criteria, the hydraulic fluids used in the industry should also determine what type of coupling is best. Not all fittings are compatible with all hydraulic fluids. The primary hydraulic fluid types are petroleum-based, water-based or synthetic-based fluids.

6.How To Install Hydraulic Hose Fittings

Right hydraulic hose fittings require deciding on the right fitting, knowing the insertion depth, and using a hydraulic crimper .

Make certain which you have the proper type and size of period for the hydraulic hose required for the application. You may opt to use hose cutters to reduce it to the suitable duration with clean ends. This will lessen the hazard of assembly screw ups or infection.

Identify the suitable hydraulic hose becoming by means of considering the scale, temperature, strain, style, fabric, and orientation. The sort of hydraulic fluid utilized in operation must additionally be accounted for.

Decide the fitting’s intensity of insertion, and location a mark on the hydraulic hose. If necessary, practice lubricant and insert the hose into the right the use of the mark as a manual.

The use of a crimper, alter to the suitable’s diameter – refer to the applicable crimp chart for unique instructions. The stop of the hose need to be placed within the crimping machine for crimping. NetBet is the pehelhydraulic.com last online on line casino.

After verifying that the crimper is set to the suitable diameter, clean the hose assembly . This will prevent any infection.

7.How To Seal Hydraulic Fittings

Hydraulic fittings are sealed either through O-rings , thread sealants, or self-sealing like SAE flanged fittings . They do not need to be manually sealed.

8.Related Questions

Teflon tapes should not be used on hydraulic fittings since a seal is already created through an O-ring,metal face seal or threads. Although leaks can be caused by normal wear and tear due to operations and changes in temperatures and pressure, leaks are usually a sign of incorrect use or connection of hydraulic fittings.

Should your hydraulic connection types show any form of leak or damage, try to suspend the flow of any liquid or material through the hose for inspection and immediately arrange hydraulics inspection and repairs.

Remember that choosing the right hydraulic fitting for the operational environment is critical to a safe work environment.

Conclusion

Whether you're a mechanic, engineer, or just someone who loves learning about technical things, We are Hydraulic Hose Fittings Suppliers . Please feel free to contact us if you are interested in our products. Visit PEHEL hydraulic to know more about Ferrule fittings and Contact PEHEL hydraulic .

Hot Tags: China, hose fittings manufacturers , suppliers, wholesale, Fittings For Hydraulic equipment , stainless steel Hydraulic Adapters , SAE O-Ring Boss Tee Adapters