Can I Reassemble or Do I Need to Replace My Hydraulic Fitting

Performing regular maintenance on your hydraulic system can prevent problems and maximize uptime. When your maintenance involves hose changes or dis-assembly of your hydraulic fittings, it’s a good idea to consider using new fittings when you reassemble your connections. But, thanks to stronger materials and advances in the design and manufacturing process, hydraulic fittings that are in working order may be reused.

Check Fitting Condition

If you are reassembling a fitting, it is critical that you have a proper seal. When considering reusing a fitting, thoroughly inspect the fitting for any signs of wear or damage. Be critical and err on the side of caution – if you question the viability of the fitting in any way, replace it. If any of the following are present, the hydraulic fitting should be replaced.

1. Nicks or damage to any sealing surface (Seats, O-Ring Grooves, etc.)

2. Corrosion, rust, or material deterioration

3. Cracks or dents or any damage to the shape of the fitting

4. Thread wear or distortion

5. Nose collapse and hole reduction

Tapered Thread Pipe Fittings and JIC 37 Flare Fittings

There are two types of fittings that are not recommended for reassembly – tapered thread pipe fittings and JIC 37 Flare Fittings.

Tapered thread pipe fittings thread into each other, sometimes supplemented with tape or paste, to make a seal. These connections rely on deformation of the sealing surfaces (the threads) to obtain a seal and can be easily worn out with repeated assembly and dis-assembly. If there is excessive wear on the threads, missing threads, or if you require multiple rounds of tape or paste to achieve a seal, the fittings should be replaced.

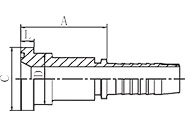

JIC 37 flare fittings use a cone and flare connection to seal. Each time the connections are fit together there is slight deformation of the 37° sealing surface to obtain a seal. Excessive torque can result in bore collapse. The collapsed fittings can result in reduced fluid flow and an insufficient seal. Measure to make sure the nose hasn’t collapsed more than 10% from its original hole diameter, and that there is no damage to the 37° sealing surface.

Straight Tread O-Ring and ORFS Connections

Straight thread O-Ring port, both inch and metric, and O-Ring Face Seal connections are designed with re-assembly in mind. These connections do not rely on mechanical deformation to obtain a seal. However, they should be well inspected for any damage that may have occurred during use. Air-Way does not recommend re-using the O-Ring, which should always be replaced prior to re-use of the fitting.

Reassembly Best Practices

Hydraulic fittings must be thoroughly cleaned before reuse. Any dirt, liquid or debris that is on the fitting has the potential to enter the hydraulic system and cause damage. When you reassemble a fitting, test your connection, and observe operation to ensure the seal is tight. If there are any leaks, replace the fitting immediately.

The best practice is always to replace a fitting, but if you do reuse a fitting be sure you are following the proper procedures for reassembly. Never mix fittings from different manufacturers or use a “close enough” fitting. Always use the correct fitting. If you must replace a hose because of damage or failure it is also best to replace the fitting to ensure a tight seal. Always follow your organization’s policies for proper maintenance and equipment use, as well as following instructions and recommendations from your equipment manufacturer.