Hydraulic Connections

Hydraulic hoses are tubes designed to transport fluids from one place to another. They are used for low, medium, high and extreme pressure. These can have from one to four braided metal meshes depending on the pressure required.

These are the most flexible part of a hydraulic system (or circuit), but also the weakest. Hydraulic hoses are designed and built under safety standards and meeting certain requirements such as:

> Security

> Flexibility

> Performance

> Endurance

> Durability

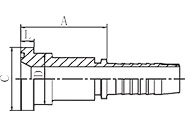

> Hydraulic hoses

Types of hydraulic hoses

> Medium pressure hydraulic hoses: their construction is based on a steel braid with a thin and flexible cover, which facilitates the routing of assemblies in the equipment.

> Low pressure hydraulic hoses: designed to be used in different applications with operating pressures below 300 PSI.

> High Pressure Hydraulic Hoses: These are called two-wire hoses because they are generally reinforced with two braids of high-tensile steel wire.

> Extreme Pressure Hydraulic Hoses: – Extreme Pressure and Very High Pressure hoses are used for construction equipment and heavy-duty machinery where high impulses or pressure surges occur.

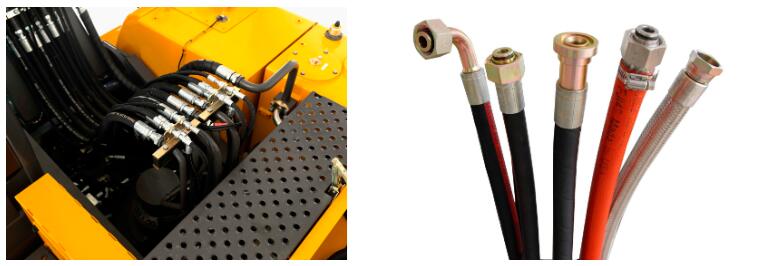

Hydraulic Connections

Leaks in hydraulic connections have come to be regarded as a characteristic of hydraulic power systems . While this was true 30 years ago, advances in sealing technology and the development of more reliable connection systems make leak-free hydraulic installations possible.

Trusted Connections

The reliability that there will be no leaks begins at the design stage, when the type of connector to be used is selected according to the port, or the connections at the ends of the pipe or hoses.

Ports – The most reliable connectors in terms of the sealing they provide are those that include an elastomeric seal, such as the straight thread with O-ring , the BSPP (British Standard Pipe Parallel) thread or the SAE four-bolt flanges .

NPT (National Pipe Tapered ) connectors are the least reliable in hydraulic systems that will handle high pressure, because the thread itself is a leak path. The threads deform when the connectors are tightened and therefore any tightening or loosening of the connector will increase the possibility of a leak.

Therefore, in systems that are already in operation, efforts should be made to replace NPT-type connections with connectors that include an elastomer seal.

Pipe and Hose Ends – ORFS (O-Ring Face Seal) pipe and hose connectors also provide the reliability of elastomeric sealing but due to their high cost, they are not as widely used as 37° JIC connectors. angle (SAE J514 37°).

The 37° JIC connections have gained wide acceptance due to their simplicity and low cost; however, the metal-to-metal seal it provides means that a leak-free joint is not always achieved, especially in the case of pipe connections.

This leak problem with 37° JIC connections can be solved with a seal developed for this purpose by Flaretite. The Flaretite seal is a 304 stainless steel ring that fits the 37° angle and has concentric machined steps that have a pre-applied sealant. When tightening, the rings press between the two faces of the joint, eliminating misalignment and surface imperfections. The combination of pressure on the rings and the sealant ensures a leak free joint.

Wrong Torque

A very frequent reason for leaks in connections between metal-to-metal surfaces is the application of an incorrect torque; On the one hand, if the torque is less than required, there will be inadequate contact between the surfaces and on the other, excessive torque will damage both the tube and the connector. Here is a simple method to ensure that the torque applied to the connector is correct:

> Tighten the hexagonal barrel until it contacts the seat.

> Using a marker, draw a straight line on the hexagonal barrel and connector.

> With the appropriate tool, tighten the hexagonal barrel

Vibration

Vibration can affect the installation, causing connectors to loosen and leaks. Installations with pipes are much more sensitive to vibration than those with hoses. If the vibration is excessive, the source of the vibration should be located and corrected. Make sure all piping is properly supported with clamps and in very extreme cases, replace pipe runs with hoses.

Seal Damage

Although we have highlighted the benefits of connectors that include an elastomer seal, it is important to note that their reliability will be directly related to keeping the hydraulic fluid temperature within acceptable limits. A single case of extreme temperature outside the permissible limits can damage all the seals in a hydraulic system, after which numerous leaks will appear in your installation.

Conclusions

A leak-free hydraulic system should be considered as a rule when designing machinery and not as an exception. For this, the proper selection of connections, their correct installation and good maintenance are essential to guarantee the reliability that the system will always be free of leaks.

Whether you're a mechanic, engineer, or just someone who loves learning about technical things, We are Hydraulic Hose Fittings Suppliers . Please feel free to contact us if you are interested in our products. Visit PEHEL hydraulic to know more about Ferrule fittings and Contact PEHEL hydraulic .