- Correct Assembly Installation

.jpg)

Since hose may change in length from +2% to -4% Under the surge of high

pressure,provide sufficient Slack for expansion and contraction.jpg)

Hose should not be twisted.Hose is weakededwheninstalledinbwistedposition

Also Pressure in twisted hose tends to loosen fitting Connections

Design So that machine motion produces bending rather that bwisting.jpg)

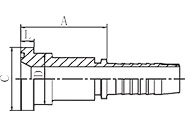

Never use a bending radius less than minimum shownin the hose

specilcationthe bending radius of hose should be far away from the

hose fitting (A>1.5R)..jpg)

Leave proper Length when the hose is connected.jpg)

Hose bending radius is bigger when it is in motion.jpg)

Choise proper fittings,avoid too small bending

radius and excess force.jpg)

Choice proper fittings,avoid twisting in hose lines

bent in two planes.jpg)

Choice proper fittings,avoid excessive hose length

.jpg)

Avoid twisting in hose by using clamp properly

.jpg)

Reduce friction,avoid hose touching the object

directly or far Bway from the object